A team of engineers at Penn State University has developed a means for electric vehicle owners that will help them to recharge their lithium-ion battery cars in just 10 minutes. Thanks to this new engineering breakthrough, take a 10-minute rest and a cup of coffee and drive out with a fully charged battery.

“We demonstrated that we can charge an electrical vehicle in ten minutes for a 200-300 mile range” said Chao-Yang Wang, professor of chemical engineering and professor of materials science and engineering at Penn State, said in a statement.

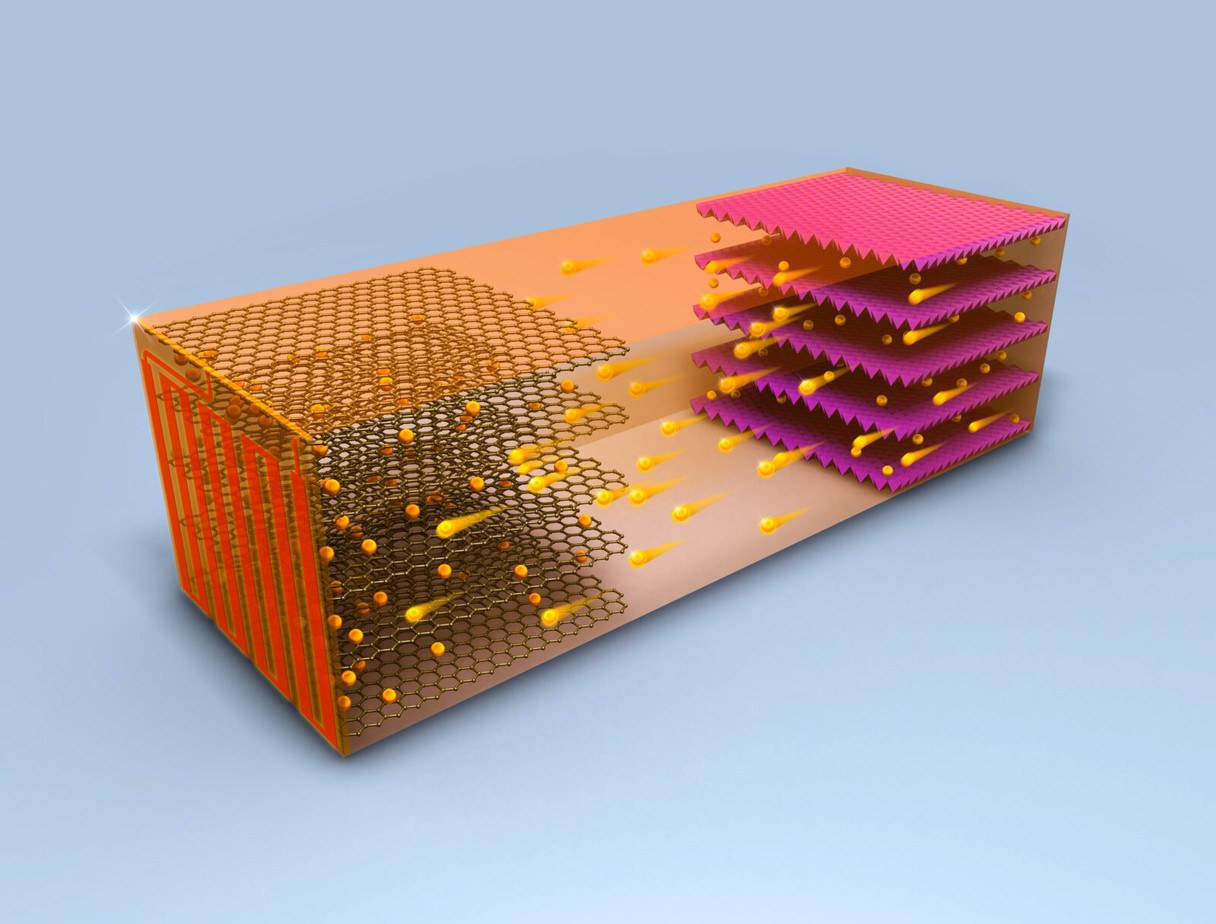

The research, published Wednesday in Joule, shows the technique could work while maintaining 2,500 charging cycles or the equivalent of half a million miles of travel. Lithium-ion batteries degrade when quickly charged at ambient temperatures under 10 degrees Celsius because, rather than the lithium ions easily being inserted into the carbon anodes, the lithium deposits in spikes on the anode surface. Read our in-depth article about “How a Car Battery Works?”

10-minute Electric Vehicle Charging: How the Breakthrough Works?

This lithium plating decreases cell capacity, but also can cause electrical spikes and risky battery conditions. Batteries heated above the lithium plating threshold, whether by external or internal heating, will not exhibit lithium plating. The researchers had previously developed their battery to charge at 10 degrees Celsius in just 15 minutes. Charging at higher temperatures would be more effective, but long periods of high heat also damage the batteries.

“Related article: Electric Car Batteries – Types, Lifespan, Maintenance and More”

Wang and his team discovered that if the batteries could heat up to 60 degrees Celsius for only 10 minutes and then promptly cool to ambient temperatures, lithium spikes would not form and heat degradation of the battery would also not happen.

“Taking this battery to the extreme of 60 degrees Celsius (140 degrees F) is forbidden in the battery arena,” said Wang. “It is too high and considered a danger to the materials and would shorten battery life drastically.”

The quick chilling of the battery would be accomplished using the built-in cooling system designed in the vehicle, explained Wang. The large difference from 60 degrees to about 23.8 degrees Celsius will also help raise the speed of cooling.

“The 10-minute trend is for the future and is essential for adoption of electric vehicles because it solves the range anxiety problem,” said Wang.

“Related article: How Do Electric Vehicles Work?”

However, this is not the first time to heat a battery and improve battery recharging time. A similar system was announced by Tesla in March 2019. Tesla was able to drop the average recharging time (paired with a new 250 kW supercharger station) down to 15 minutes.

Wang’s team used a thin nickel foil with one end attached to a negative terminal and the other to a third terminal outside the cell. Electrons flowing through the foil result in resistance heating in the foil, which makes the battery warm-up. The battery could avoid heat degradation through rapid cooling after the charging was complete. This would use the built-in car’s cooling system to bring it down to allowed temperatures.

![Types of Engineers and What they Do [Explained]](https://www.engineeringpassion.com/wp-content/uploads/2022/04/types-of-engineers-and-what-they-do-280x210.jpg)

Leave a Reply